- Ferrosilicon

- Silicon metal

- High Carbon Silicon

- Silicon carbide

- Silicon calcium

- Ferroalloy Briquette product

- silica fume

- Carbonizer

- Magnesium ingot

- Calcium silicon alloy cored wire

- Silicon slag

- Nodulizer and Inoculant

- Slag Stopping Ball

- Slag stopping plug

- Nozzl

- Zirconium nozzle

- Hotline

- +86-15517207844

- +86-372-2958995

- Official email:

admin@ayxlsyj.com - Sales mailbox:

sales@ayxlsyj.com

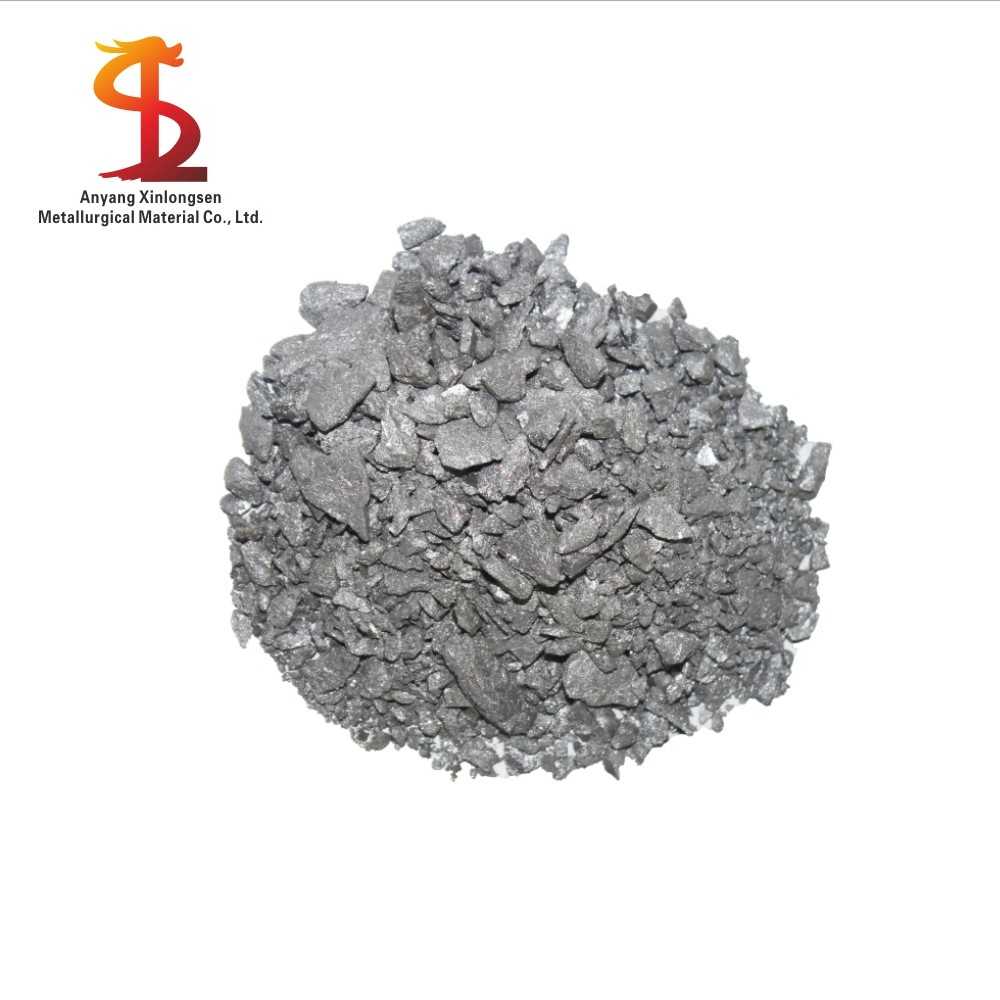

Silicon metal

Silicon metal

Silicon is widely used in smelting ferrosilicon alloys as alloying elements in i

Silicon is widely used in smelting ferrosilicon alloys as alloying elements in iron and steel industry, and as reducing agents in many metal smelting. Silicon is also a good component in aluminium alloys, and most cast aluminium alloys contain silicon. Silicon is the raw material of ultra-pure silicon in electronic industry. The electronic devices made of ultra-pure semiconductor monocrystalline silicon have the advantages of small size, light weight, good reliability and long life. High-power transistors, rectifiers and solar cells made of silicon single crystals with specific trace impurities are better than those made of germanium single crystals. The research progress of amorphous silicon solar cells is very fast. The conversion rate of amorphous silicon solar cells is over 8%. The temperature of silicon-molybdenum rod electrothermal element can reach 1700 C, which has resistance, aging resistance and good oxidation resistance. Silicon trichloride produced from silicon can be used to prepare hundreds of silicone resin lubricants and waterproof compounds. In addition, silicon carbide can be used as abrasive. Quartz tubes made of high purity silicon oxide are important materials for high purity metal smelting and lighting lamps. Silicon, the paper of the 1980s, is called "paper of the 1980s". This is because paper can only record information, and silicon can not only record information, but also process information to obtain new information. In 1945, the world's electronic computers, equipped with 18,000 tubes, 70,000 resistors and 10,000 capacitors, weigh 30 tons and cover 170 square meters, equivalent to the size of 10 houses. Today's computers, due to technological advances and material improvements, can accommodate tens of thousands of transistors on a silicon chip the size of a nail cap, and have a series of functions such as input, output, operation, storage and control information. Microporous calcium silicate insulation material Microporous calcium silicate insulation material is an excellent insulation material. It has the characteristics of small heat capacity, high mechanical strength, low thermal conductivity, non-combustion, non-toxic, odorless, cutting, convenient transportation, etc. It can be widely used in metallurgy, power, chemical industry, ships and other thermal equipment and pipelines. The test shows that the energy-saving benefit is better than that of thermal insulation materials such as asbestos, cement, vermiculite and cement perlite. Special calcium silicate materials can be used as catalyst carriers and are widely used in petroleum refining and automobile exhaust purification.

| Chemical Composition(%) | ||||

| Grade/spec | Si | Fe | Al | Ca |

| 553 | 98.5%min | 0.5%max | 0.5%max | 0.3%max |

| 441 | 99.0%min | 0.4%max | 0.4%max | 0.1%max |

| 3303 | 99.0%min | 0.3%max | 0.3%max | 0.03%max |

| 2202 | 99.0%min | 0.2%max | 0.2%max | 0.02%max |

| 1101 | 99.0%min | 0.1%max | 0.1%max | 0.01% |

| 98 | 98%min | 1.0%max | 0.8%max | 0.3%max |

- Prev: Silicon metal

- Next: Silicon metal